| ELECTRICAL SPECIFICATIONS |

| ± 5% standard on values 1 ohm and above. |

| ± 10% standard on values below 1 ohm. |

| Temperature Coefficient: |

| ± 90PPM/° C, below 1 ohm. |

| ± 50PPM/° C, 1 ohm to 9.9 ohm. |

| ± 30PPM/° C, 10 ohm and above. |

| Dielectric Strength: |

| 1000VAC minimum |

| Short Time Overload: |

| Any intermittent duty the applied power can greatly exceed the wattage rating. However, since each pulse application is somewhat unique, the factory should be consulted for specific requirrements. |

| MATERIAL SPECIFICATIONS |

| Core: Steatite. Chemically inert - will withstand severe thermal shock and is impervious to moisture. |

| Element: Highest quality copper-nickel alloy or nickel-chrome alloy, depending on resistance value. Special alloys available upon request. |

| Coating: Special high temperature silicone. |

|

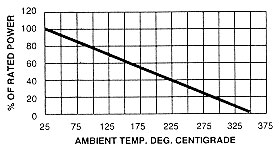

| DERATING |

| Industrial wirewound resistors have an operating temperature range of - 55° C to + 350° C. They must be derated at high ambient temperatures according to the curve below |

|

|

| HOW TO ORDER: |

| Example: 30W 10 ohm 5% |

|

FPL30

|

10R0

|

J

|

|

P/N

|

Resistance

4 digit <100 use R use R

for decimal. >100 4th digit is multiplier 4th digit is multiplier

|

J=5%

K=10% |

|

|

|

|

|

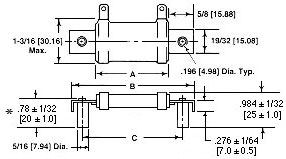

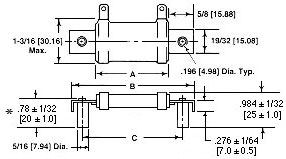

* FOR MODIFIED POSTS CUT TO 11.0±1.0MM IN LENGTH, ADD LETTER M AFTER WATTAGE

EXAMPLE: 40W 30 OHM 5% FPL40M-30R0J

|

|

|